Acoustic Emission Testing

02 Oct 2022 Download PDF

What is meant by Acoustic Emissions?

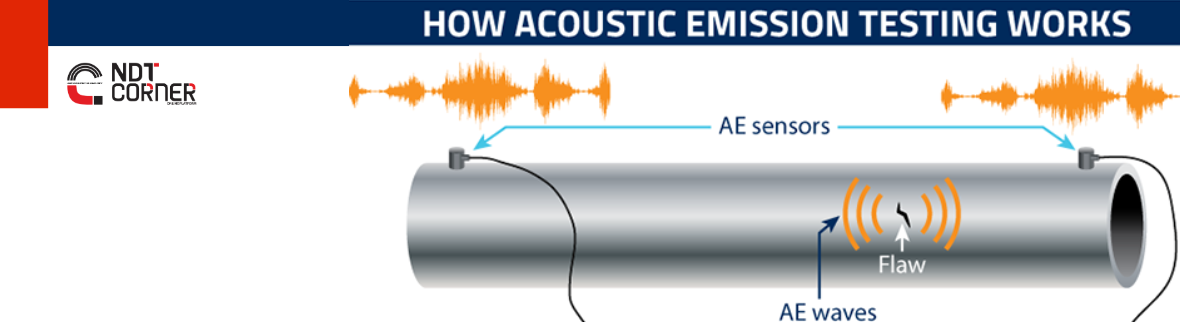

Acoustic Emission (AE) refers to the generation of transient elastic waves produced by a sudden redistribution of stress in a material. When a structure is subject to an external stimulus (change in pressure, load, or temperature), localized sources trigger the release of energy, in the form of stress waves, which propagate to the surface and are recorded by sensors. With the right equipment and setup, motions on the order of picometers (10 – 12 m) can be identified. Sources of AE vary from natural events like earthquakes and rock bursts melting, twining, and phase transformations in metals. In composites, matrix cracking and fiber breakage and debonding contribute to acoustic emissions. AE’s have also been measured and recorded in polymers, wood, and concrete, among other materials.

Detection and analysis of AE signals can supply valuable information regarding the origin and importance of a discontinuity in a material. Because of the versatility of Acoustic Emission Testing (AE), it has many industrial applications (e.g. assessing structural integrity, detecting flaws, testing for leaks, or monitoring weld quality) and is used extensively as a research tool.

Acoustic Emission is unlike most other nondestructive testing (NDT) techniques in two regards.

-

1st pertains to the origin of the signal. Instead of supplying energy to the object under examination, AET simply listens for the energy released by the object. AE tests are often performed on structures while in operation, as this provides adequate loading for propagating defects and triggering acoustic emissions.

-

2nd difference is that AET deals with dynamic processes, or changes, in a material. This is particularly meaningful because only active features (e.g. crack growth) are highlighted. The ability to discern between developing and stagnant defects is significant. However, it is possible for flaws to go in detected all together if loading is not high enough to cause an acoustic event. Furthermore, strength or risk of failure of a component. Other advantages of AET include fast and complete volumetric inspection using multiple sensors, permanent sensor mounting for process control, and no need to disassemble and clean a specimen.

What is Acoustic Emission Testing?

The term acoustic emission testing (AET) refers to the procedure of inspecting and recording acoustic emissions utilizing specialized tools. This is a type of non-destructive test (NDT) that has many uses, encompassing assuring the structural integrity of vessels, monitoring the quality of the weld and much more. The method includes the utilization of sensors to identify AE and accordingly transform the waves into electrical signals in order to record them. After that, the results can be analyzed to evaluate the condition of the material and find any flaws. The recorded data can give valuable information about the lineage and importance of a defect present in the material.

Principle Of Acoustic Emission Testing

When a material with defects is subjected to mechanical stress or load, it releases energy. This energy travels in the shape of high-frequency stress waves. These waves or fluctuations are obtained with the utilization of sensors which in turn transforms the energy into voltage. This voltage is electronically overstated with the utilization of timing circuits and later refined as acoustic emission signal data.

Advantages Of Acoustic Emission Testing:

Acoustic emission testing can be utilized for the timely identification of any defects & real-time monitoring as well. It is a high-sensitivity test technique and delivers various advantages, as mentioned below:

-

Timely damage detection - As acoustic emission testing inspects the formation of cracks & defects, and as mentioned above that it is a highly sensitive test method, it can detect fairly small/micro defects in the initial stage. This early detection encourages you to fix up the flaws before they cause any crucial problems or threats.

-

Global, simultaneous examination - With the help of AET, you can analyze the whole unit or system simultaneously, comprising pressure vessels, piping, reactors and any other extra elements. This actually leads to a more productive, cost-effective testing procedure and facilitates the assessment of even large systems somewhat instantly.

-

No need for stopping the operation - AET can often be executed on a unit while it is functioning, averting the necessity for shutting down a system. One can even conduct acoustic emission testing at the time of an in-service over-pressurization or scheduled cool-down. Preventing a shutdown of the machines can decrease costs considerably and will help you keep a consistent productivity level.

-

Detection of only active flaws - Acoustic emission testing only specifies active deformities means those defects that are thriving. This characteristic shows that only flaws that are liable to cause critical problems in the future are detected, whereas stable cracks and former fabrication flaws are not. This facilitates you to concentrate on the most important problems, conserving the time and money of your business.

-

Immediate indication of threat - When it comes to acoustic emission testing, you get a sudden indication of the stability & strength of a provided component and the risk of disappointment or failure, encouraging you to react promptly if required.

-

Minimal disruption to insulation - Usually, only minor holes in insulation are needed to mount sensors. You might also be eligible to park permanent sensors under the insulation.

-

Compliance assistance: Various standards recognize acoustic emission testing, and it can help you to ensure compliance with federal, state and local regulations.

-

Decreased expenses - Utilizing acoustic emission testing can decrease costs significantly by preventing downtime, curtailing examination time, expecting the smallest disruption to insulation, and specifying only the deformities that may result in substantial problems in the near future if not amended.

Limitations Of Acoustic Emission Testing:

Like any other test method, acoustic emission testing also has some limitations, which indicates it might not be the perfect option for every application. In some circumstances, organizations can profit from supplementing acoustic emission testing with other examination methods. Some of the disadvantages/limitations of acoustic emission testing are as follows:

-

Can only provide qualitative results - Acoustic emission testing can only deliver qualitative outcomes and not quantitative results. It can actually detect that a flaw still exists, but specifying the size and depth of a crack, for instance, requires other examination methods, just like ultrasonic testing.

-

Can only find active flaws - The fact that acoustic emission testing only detects active flaws can actually be an advantage, but in some situations, you might also wish to identify stagnant imperfections. Acoustic emission testing would not help this objective. It is furthermore possible that AET may not observe very small active defects if the loading is not sufficient to result in an acoustic circumstance.

-

Loud environments present challenges - It can be extra challenging to obtain precise findings from acoustic emission testing when it is conducted in loud service atmosphere settings. In order to filter out surplus noise, signal discrimination and noise reduction methods and technologies are employed.

-

Requires certain skills, knowledge and proficiency - Conducting AET needs a highly-skilled, experienced, and knowledgeable operator. It also includes the utilization of relatively complicated and costly software and hardware.

Applications of Acoustic Emission Testing

It's a known fact that acoustic emission testing is versatile and has numerous applications in various industries. It is also used as research equipment. Now, let's read about a few applications of acoustic emission testing that are listed below:

-

Identification of active sources that includes crack propagation, fatigue, fiber delamination, yielding, fiber fracture, corrosion, and creep.

-

Leak detection. Laboratory and research and development (R&D) studies.

-

Weld quality monitoring.

-

In-field examination.

-

Structural integrity inspection.

-

Production quality supervision.

-

Monitoring chemical reactions and phase changes.

-

Leak detection.

Industries categories that can use acoustic emission testing includes:

Aerospace: The aerospace field can employ acoustic emission testing to evaluate fuel storage tanks and motors.

Alternative energy sources: Acoustic emission testing is beneficial for assessing the structural integrity of alternative energy infrastructure, just like wind turbines.

Automotive: Automotive manufacturers can make use of acoustic emission testing to evaluate vehicle elements and factory equipment as well.

Materials research and development: Those who are working in materials research and development, can make use of the AET method to examine the integrity of brand new materials as well as existing materials in numerous applications.

Nuclear power: In order to inspect nuclear components like valves, lift beams, and streamlines AET can be utilized.

Offshore drilling: This particular non-destructive method can give early detection of drawbacks in offshore drilling pipelines and platforms.

Oil and gas: AET can be used by oil and gas companies to assess processing equipment, vessels, and pipelines.

Power distribution: Acoustic emission testing can be utilized in power transformers for partial discharge inspection.

AE systems can only qualitatively gauge how much damage is contained in a structure. In order to obtain quantitative results about the size, depth, and overall acceptability of a part, other NDT methods (often ultrasonic testing) are necessary. Another drawback of AE stems from load service environments which contribute extraneous noise to the signals. For successful applications, signal discrimination and noise reduction are crucial.